그라우팅펌프 및 믹서교반기

본문

Grouting Pump & Mixer

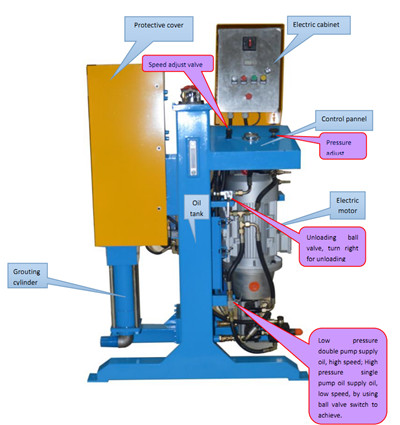

Grout pump for micro piping

Gaode grout pumps are available in various sizes and power ratings with grout injection pressures up to 450 bar and flow rates up to 210lt/min.

Grout machine can easily meet all the main requirements for low, medium and high pressure applications such as micropiling, anchoring injections,

permeation grouting, compensation grouting, grout filling (e.g. cavities in mines, tunnels, etc.), drilling mud injections, etc.

In particular, for micro piping works, more powerful GDH75/100 grout pump for micro piping is widely used.

Adjustable flow and pressure: Low pressure 0-50Bar/725psi, flow rate: 0-75L/min; High pressure: 0-100Bar /1450psi, flow rate 0-40L/min.

Grout pumps can working with match grout mixer and agitator, this can ensrue a continous mixing and grouting projects.

Grouting recorder can also working together with the machine, it can recorder the flow and pressure.

Bentonite mixing and pumping machine for build tunnel

Our GAODETEC equipment make bentonite mixing and pumping machine for build tunnels.

Herrenknecht China company used our GGP400/700/80PL-E bentonite mixing and pumping machine when build tunnel.

The bentonite mixing and pumping machine has following advantages:

1 Continuous output with small pulse or kicks or jerks.

2 Grouting pressure and flow both could be adjust step-less.

3 High speed vortex mixers ensure mixing evenly and quickly.

4 Grout mixer and agitator switch by using squeeze handle, easy to operate, safe and reliable.

5 The motors with overload protection function.

6 The hydraulic system with oil temperature overheating protection.

7 Les spare parts make sure the machine with low maintenance costs.

In one word, the grout machine with simple structure, compact size, light weight, easy maintenance etc. features in one.

So please contact us now for one suitable bentonite mixing and pumping machine for grouting bentonite slurry when build tunnels.

The bentonite mixing and pumping machine has following advantages:

1 Continuous output with small pulse or kicks or jerks.

2 Grouting pressure and flow both could be adjust step-less.

3 High speed vortex mixers ensure mixing evenly and quickly.

4 Grout mixer and agitator switch by using squeeze handle, easy to operate, safe and reliable.

5 The motors with overload protection function.

6 The hydraulic system with oil temperature overheating protection.

7 Les spare parts make sure the machine with low maintenance costs.

In one word, the grout machine with simple structure, compact size, light weight, easy maintenance etc. features in one.

So please contact us now for one suitable bentonite mixing and pumping machine for grouting bentonite slurry when build tunnels.

Any question or any demands on the bentonite mixing and pumping machine,

please email us without any hesitation, once confirm the detailed requirements on the bentonite mixing and pumping machine, more better solution will be offered to you at first time.

High Pressure Jet Grouting Pump Application

GAODE Equipment high pressure jet grouting pump were widely used in jet grouting work. Because of high pressure, high flow,

the jet grouting pump were applied on ground treatment and stabilization of railway, highway, bridge, dam, industrial and civil buildings, geological disaster control etc. projects.

The high pressure jet grouting pump with following features and advantages:

a. Advanced AC variable-frequency technique, stepless speed regulation, steady to start and run, and no surge for power network;

b. Flow rate and pressure could be controlled automatic, perfect protection, safety and save energy and save cost (don’t do idle work, the power is working power).

c. With simple structure, easy to operate, high efficiency;

d. With new type pump parts, easy and speedy for disassemble and exchange, low maintenance costs.

Some cases of the high pressure jet grouting pump High pressure jet grouting pumps were used to improve soil strength for build metro projects in Xian city.

High pressure jet grouting pumps were used for ground treatment and stabilization.

High pressure jet grouting pumps were used in Tibet for geological disaster control.

Gaode Equipment as one high pressure jet grouting pump factory, make many types grout pump for sale.

If you want one right high pressure jet grouting pump for your project, please help us to confirm the following points:

1 what is the pressure do you demands?

2 what is the flow do you demands?

3 would you like the injection grout pump with electric motor or diesel engine or air motor?

If want the injection grout pump wok with electric motor, also please confirm the voltage at the worksite.

If you don’t know this information, also please don’t worry, Gaodetec also has its own technical team and with research and development ability,

please send your project demands on the high pressure jet grouting pump, we will recommend the suitable type or design suitable high pressure jet grouting pump according to your demands.

So any question or any demands on the high pressure jet grouting pump, please contact us without any hesitation,

once confirm the detailed needs on the high pressure jet grouting pump, better solution will be offered to you at first time.