Slurry Transfer Pump

Content

Model : STP-300

STP Sewage Slurry Transfer Pump

STP Sewage Slurry Transfer Pump can be used for the following purposes:

Cement grouting injection

Mortar pumping injection

Mud pumping transfer operation

Pressure grouting

Removal of slurry from tunnel site, etc.

Slurry Transfer Pump

Model : STP-300

STP300 power 75kw motor 10hp / Max. discharge 30m³/h / Max. pressure 50 bar / Max. transfer distance 150m Powerful force,

hydraulic discharge control, and safe 24-hour operation.

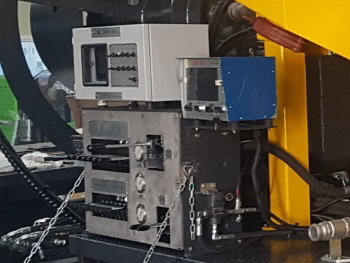

Slurry Transfer Pump is divided into these parts:

Base frame, hopper, hydraulic cylinder, plunger cylinder, water box, S-valve, piston ram, hydraulic valve, automatic grease filler.

Slurry Transfer Pump

Model : STP-300

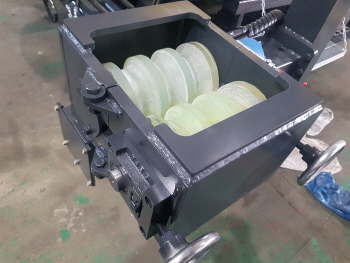

Dehydrated Cake slurry device transfer pump

Is composed of sludge bunker feeder body, double screw feeder, feeder, shaft, divider gearbox, reducer and hydraulic motor

The sludge bunker feeder is installed on the top of the sludge transfer pump to pressurize the sludge emitted from the sludge bunker into

the hopper of the sludge transfer pump, increasing the uniformity

and efficiency of the transfer volume of the sludge transfer pump and enabling smooth sludge transfer.

The rotational speed of the double-screw conveyor is adjustable and interlocked with the transfer speed of the sludge transfer pump.

The screw conveyor is designed with integral screw wings so that the sludge can be transported continuously.

Main resources can be changed depending on site conditions.

Specification | ||

Model | STP-300 | |

Electric motor | kw | 75 |

Pump specification | mm | TBP140 *A10V28DP*GEAR10 |

Length | mm | 5200 |

Heigh | mm | 2300 |

Width | mm | 1100 |

Pump Cylinder Diameter x stroke | mm | 230×1200 |

Number of pump cylinders | ea | 2 |

Hydraulic Drive Cylinder Bore | mm | 100 |

Transfer Conveyor Cylinder Bore | mm | 180 |

Max. horizontal travel distance | m | 150 |

Max. vertical travel | m | 102(max) |

Hopper capacity | l | 0.31 |

Transportation | A | 5“ |

Max. aggregate size | mm | 5 |

Transportable slump | cm | 12~23 |

Hydraulic tank capacity | l | 800 |

Main block | l | NG16 valve |

Discharge control | mA | 4~20 |

Geothermal Grouting Pump

Model : GPX-2200

The maximum discharge and the maximum distance of the geothermal grouting mixer pump is possible to manufacture by field specifications.

Can work various tasks, such as slurry cement milk grout pump, mortar grouting pump, etc.

With the PLC computer program, silica sand, bentonite, liquid fire, water,

and each usage of those are numerically shown in the LCD window and total usage is calculated.

All materials on the centralized high-efficiency grouting control panel are quantitatively injected to pump the mixer and can print the total workload.

Control the condition of the optimal mixing of PLC touch screen automatic metering system and silica bentonite.

C-linked printing system

centralized control panel

Control Bentonite Discharge

Control Silica Sand Emission

Control Flowable fire Discharge

Water discharge control

Inserting roll with minimal damage to the insertion tube of the transfer hose roll system

Specifications | |

Model | GPX-2200 |

Power | 380V/Three phase |

Motor | 100 HP |

Electric power | 75 kw |

Discharge | 0-850 Liter/min |

Max. horizontal distance | 2000 m |

Max. vertical distance | 800 m |

Hydraulic cylinder | 110 mm |

Administrative distance | 1400 mm |

Inlet | 4“ (100mm) |

Discharge outlet | 3“ (76mm) |

Hose reel | 150 m |

Outrigger | 4개 x 1500 mm |

Size | 2850 x 2300 x 1950 mm |

Weight | 3500 kg |

Jet Grout Pump

Model : GPX-2000

This machine can work various tasks, such as Ground Reinforcement eco-friendly grouting mixer pump GPX-2000,

Slurry cement milk grout pump, Mortar grouting pump, etc.

With the PLC computer program, silica sand, bentonite, liquid fire, water, and each usage of those are numerically

shown in the LCD window and total usage is calculated.

The four outriggers with self-lift loads themselves onto a 2.5-ton vehicle.

The high-pressure pump is designed to the most advanced building standards.

Specifications | |

Model | GPX-2000 |

Power | 380V/Three phase |

Motor | 80 HP |

Electric power | 60 kw |

Discharge | 0-600 Liter/min |

Max. horizontal distance | 1000 m |

Max. vertical distance | 400 m |

Hydraulic cylinder | 100 mm |

Administrative distance | 1250 mm |

Inlet | 3“ (76mm) |

Discharge outlet | 3“ (50mm) |

Hose reel | 150 m |

Outrigger | 4개 x 1500 mm |

Size | 2700 x 2300 x 1950 mm |

Weight | 2800 kg |